Kreyenborg is a leading provider of solutions in the field of bulk material handling. Kreyenborg reduces germs, decontaminate, dry, disinfects, opens aromas, roast and toast.

Bulk Material Handling

Germ Reduction

For the first time, food in a bulk form such as tea, leaves, herbs, dried vegetables, dried mushrooms, nuts, pits, seeds, grain, cereals, spices, and cut chopped and powdered food can be treated using infrared light in such a way that the microbiological load is drastically reduced and even contaminants are partially dissolved and evaporated.

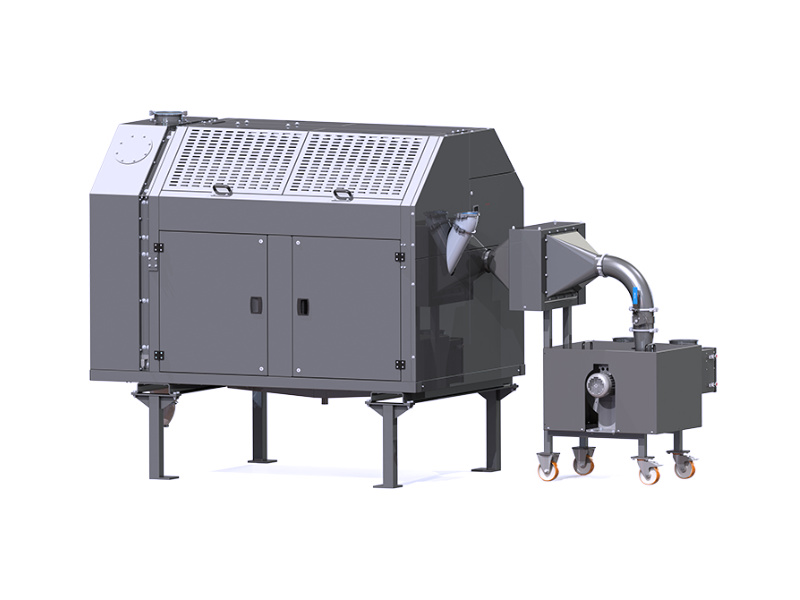

The FS-IRD system is a procedure based on infrared light. The light heats the core of the product instantaneously and leads to a reduction of the germ load.

Treatment with infrared light allows for maximum protection of optical and sensory product properties.

Ideal for Chillies, Red pepper flakes, Tea, Leaves, Herbs, Dried Vegetables, Grains and Seeds.

How our thermal treatment solutions can help

Drying

By augmenting your convective dryer with an IRD, you can increase capacity by up to 50% and at the same time significantly improve the quality of your final product.

The final product can be dried to less than 1% in minutes instead of hours. The reverse-working principle of using infrared light improves the quality of the final product. For some products, flavours can be released during the drying process.

Disinsectization / Stock protection

The granary weevil (grain beetle) attacks grains, including wheat, rye, oats, barley, maize (corn), millet, rice, pasta, buckwheat, flour, bran, grist, almonds, peanuts, peas, beans, and soy.

Our technology will ensure the secure destruction of insects, larvae and spawners while imparting no damage to the final product. The proteins of the product will be protected.

Flavor

Conventional heat treatment and drying processes usually cause keratinization, and encapsulation of cells or particles of the product. Valuable taste and flavour substances are encapsulated in the cells and therefore difficult to Access.

These encapsulants open at least partially when treated with infrared light (heat diffusion from the inside to the outside). Aromas and flavours are newly accessible.

Roasting

In contrast to conventional convective treatments, this new procedure is not controlled using the temperature of the heat transfer medium, but rather by very fast and precise control of product temperature. Focused infrared light penetrates below the surface of the product particles and is thereby converted into heat in the interior. In a very short time and with maximum protection of the product the desired degree of roasting is achieved.