ALMOND PROCESSING LINE

Almonds are a type of edible tree nut that is mostly farmed in California. The almonds are picked and brought to an almond processing line, hulled, and shelled. An almond huller/job sheller is to remove the almond's hull and shell from the nut or flesh. 10 to 25% of the field weight of material sent to the almond processing line is made up of orchard trash, dirt, and pebbles.

Clean almond meats account for around 20% of the total field weight. Processes for removing debris, as well as the hulls and shells of almonds, are potential sources of air pollution. After almonds are harvested from the field, they go through two stages of processing: post-harvest and finish. These steps are usually carried out in an almond processing line at two distinct locations.

Natural almonds can be blanched, roasted, sliced, slivered, diced, or crushed in an almond processing line for use as an ingredient or snack. Heat and/or size reduction procedures are applied to these items. Some chemical processes in the almonds may be triggered by heat treatments. The quantity of surface area exposed to air will rise due to size reduction procedures. The shelf stability of processed almond products will be affected by both processes.

Natural whole almonds have a longer shelf life than cut and roasted almonds. Processing parameters (e.g., temperature, time) and post-process management should be given specific attention to extend the shelf life of treated forms. The most prevalent process that has the biggest influence on quality is roasting.

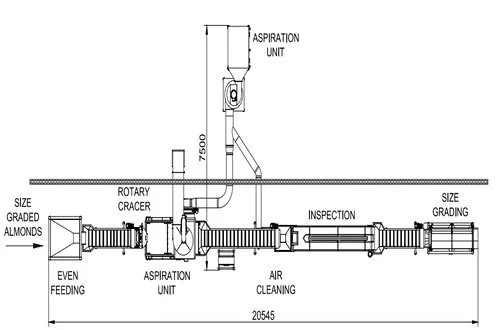

Method of Almonds Processing Line

There are two types of post-harvest processing facilities in the almond processing line for almonds: those that create hulled, in-shell almonds and those that generate hulled, shelled, almond meats. Both types of facilities perform precleaning, hulling, and separating processes on almonds in the almond processing line.

Additional processes in the huller/sheller separate the almond flesh from their shells. The hulled, shelled almond meats are delivered to a huge almond processing line, where they are further processed into numerous final products. Harvesting of almonds, as well as precleaning, hulling, shelling, separating, and final processing in the almond processing line.

The percentage of debris collected varies depending on agricultural techniques, field soil qualities, and the age of the orchard, and can range from less than 5% to 60%. On average, field weight generates 13% trash, 50% hulls, 14% shells, and 23% clean almond flesh and bits, but these ratios might vary significantly from farm to farm.

The almonds are carried to the almond processing line where they will be processed and thrown into a receiving pit. Screw conveyors and bucket elevators deliver the almonds to a series of vibrating screens. Orchard waste like leaves, dirt, and stones is carefully removed by the screens. A designer is a machine that removes bigger materials such as stones, mud clods, and other debris. Twigs and tiny sticks are removed with a retrigger.

For particle matter removal, the air streams from the different screens, designers, and det wiggers are ducted to cyclones or fabric filters. The recovered soil and fine debris, such as leaves and grass, are scattered on nearby farms to be disposed of. The twigs that have been retrieved can be chipped and utilized as fuel for cogeneration facilities. Another person transfers the precleaned almonds from the precleaned area.

Further in the almond processing line Almonds are transported to a sequence of hulling cylinders or shear rollers, which shatter the almond hulls, using belt and bucket conveyors. Hulling cylinders are commonly found in almond hulling plants. In most shellers, a series of shear rollers are employed. The hulling cylinders do not include a built-in mechanism for aspirating shell fragments. On the other hand, shear rollers feature built-in aspiration to remove shell bits from hulls and meats.

The cracked almonds are subsequently discharged to a gravity table or a series of vibrating screens, which separate the hulls and unhulled almonds from the in-shell almonds, almond meats, and fine rubbish. Additional hulling cylinders or shear rolls, as well as screen separators, are used to process the remaining unhulled almonds. The number of passes and the equipment combinations vary by facility.

The hulls are transported to storage and sold as a component in cow feed production. The acceptable waste is collected and disposed of using a cyclone or cloth filter. The hulled, in-shell almonds are separated from any leftover hull pieces in a series of air legs (counter-flow forced air gravity separators) at a hulling plant, where they are then graded, collected, and sold as a finished product, along with an unavoidable tiny proportion of almond meats.

The in-shell almonds pass through additional shear rollers and screen separators in hullers/shellers. The almond shells are split or sheared away from the flesh when the in-shell almonds move through more sets of shear rollers. The surfaces are separated from the meats and tiny shell bits by more vibrating screens. The separated shells are inhaled and collected in a cloth filter or cyclone before being transported to storage and sold as cogeneration plant fuel.

Vibrating conveyor belts and bucket elevators in the almond processing line transport the almond meats and small shell bits to air classifiers or air legs, which separate the small shell pieces from the meats. The amount of air separators varies depending on the facility. These air classifiers collect and store the shell bits they remove, which are then sold as fuel for cogeneration facilities. The profits from the selling of hulls and shells are usually enough to cover the costs of running the almond processing line.

The almond meats are next fed onto a series of gravity tables or separators, which separate the meats into four categories: lights, middlings, goodies, and heavyweights. Lights, middlings, and heavies with hulls and shells are all returned at different stages of the process. The goods are transported to the completed meat box, where they will be stored.

Any residual shell fragments are sucked and delivered to the shell storage facility. The almond meats are now available for sale as raw products or for additional processing, usually at a different location. Blanched, sliced, diced, roasted, salted, or smoked meats are all options. Small chunks of meat can be processed into flour or pastes for use in pastry items. Almonds are roasted in a revolving drum over a long period. They are carefully cooked to avoid scorching.

Almond processing line roasting Method

In the Almond processing line, Roasting is a heat treatment that changes the texture, colour, and flavour of raw California almonds. Roasted almonds have a crunchier texture, a browner colour, and a roast-flavour character that many people prefer. Depending on your application demands, almond kernels with skin or blanched can be roasted by hot air (dry roasting) or in hot oil.

Dry-roasted almonds are commonly found in chocolates, confectionery, morning cereals, and baked items, as well as snacks. Typically, oil-roasted almonds are used in ice cream and as a snack. Dry-roasted in-shell almonds can also be used for snacking.

In the Almond processing line, Almonds are usually roasted at temperatures ranging from 265 to 320 degrees Fahrenheit. Roasting almonds at low to mid temperatures of 265 to 293°F helps to retain the microstructure and extend the shelf life of the product.

To make light-, medium-, or dark-roasted almonds, several temperature and time combinations can be used. In most circumstances, the same degree of roast may be accomplished by altering the roasting time: longer roasting periods are necessary at lower roasting temperatures, whereas shorter times are required at higher roasting temperatures.

Our Principal

Kiron Food Processing Technologies, in association with Bigtem, provides a full solution for your almond processing line requirements. Bigtem is a world leader in this industry, producing processing lines for more than half of the raisins produced worldwide. With the manufacturing lines it has created in the last ten years, Bigtem has given traditional processing methods a whole new viewpoint.