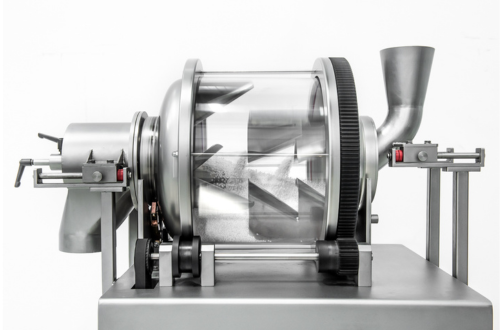

Continuous Mixer

There are various types of mixers used in food processing, coming in different sizes, shapes, and modes of operation. These mixers can be either continuous or batch mixers. Continuous mixer, as the name means, allows the continuous loading, mixing, and discharging of concrete until the quantity needed is obtained. Materials are manually loaded using screw feeders. Continuous mixing is suitable for large-scale projects like building major roads, high-rise buildings, dams, or bridges.

BASICS OF BATCH MIXING & CONTINUOUS MIXING

There are two primary methods for Handling Mixing Processes: Batch mixing and Continuous mixing. Let us break them down:

Batch Mixing

In batch mixing, each phase of the process is performed independently, with one "batch" completed before going on to the next. For example, think about making dough. You load the ingredients, mix the dough, remove it, and then start a new batch.

Batch mixing is great for smaller operations where ingredients can be managed and added by hand. It provides flexibility and precise control over each batch, with set mixing times and traceability.

However, as your operation grows and needs more ingredients and manual work, batch mixing can become inefficient.

Continuous Mixing

Continuous Mixing refers to a mechanism that constantly feeds materials to the mixer and discharges the finished result. From beginning to end, the process is continuous, with automated controls in place to manage it.

This method is beneficial for large mixing operations because it reduces mixing times and increases output capacity. Automation also reduces manual labour, saving time and resources.

However, continuous mixing may not be suitable for applications where precise recipes are crucial. It's less flexible than batch mixing and might not easily adapt to different recipes.

In summary, choose batch mixing for smaller, flexible operations, and opt for continuous mixing for larger operations with higher output demands and less emphasis on exact recipe precision.

How Continuous Mixing Works

In mixing, the movement from where we put the ingredients to where we get the final mix is made possible by the rotating mixer vessel. It spins the ingredients, making them move in a zig-zag pattern, similar to a continuous paddle mixer. How we load the material into the mixer is crucial and can greatly impact the quality of the mix we get.

As the material travels through the mixer, it undergoes axial (along the axis) and radial (from the centre outward) mixing. The time it takes for the material to go from the input to the output is called the "retention time" of the mix. In batch mixers, we can carefully control this time, but in continuous mixers, it's not consistent. Factors like how fast we add ingredients, the speed of the mixer, and how the mixer is designed can influence this retention time.

Benefits of Continuous Mixing

advantages of Continuous mixers

They can handle large amounts of material compared to batch mixers.

Mixing is quicker in continuous mixers than in batch mixers.

They provide consistent mixing performance when ingredients are added properly.

They come with automated control features, making the process easier to manage.

There is less separation of particles in the mix.

Continuous mixers are generally more affordable than batch mixers.

They are more space-efficient as they are more compact.

Less manual labour is needed compared to batch mixers.

Continuous Mixer- A great alternative for batch mixer

In a Continuous Mixer, ingredients constantly flow into the mixer from above. As they pass through the mixer, they get processed, and a continuous stream of well-mixed powder comes out from the discharge nozzle. Each stage of the process happens continuously and simultaneously within a set timeframe. Common examples of continuous mixers are granulators and powder formers. Continuous mixers are classified into numerous categories based on the qualities of the product to be mixed. Mixing can be done in phases to ensure that all materials are well combined. Continuous Mixers are self-monitoring devices that are widely utilized in the food, chemical, and plastic industries.

Industrial mixing has progressed from conventional manual methods to modern agitators. In today's fast-paced world, staying current on emerging trends is critical to being competitive. Mixing is an important procedure in several industries, including medicines and mining. This article explores the latest trends in mixing technology and how innovation is changing this fundamental industrial process.

The Gentle Touch Mixing Principle

Our mixing technology relies on gravity as the main force. Instead of using paddles or ribbons to forcefully move particles, our approach allows the product to flow and redistribute naturally. Gravity provides a consistent force, preventing localized impact, speed, and force chain reactions. This results in a more efficient and gentle mixing process. Even delicate products can be homogenized quickly without degradation, heat buildup, or hot spots.

Our Principal

Lindor Gentle Touch Technology is designed for mixing fine powders, granules, and natural products. The key advantage is its ability to achieve high homogeneity quickly while preserving the product's integrity. With our gentle mixing technology, you can efficiently produce the highest quality products. Kiron Food Processing Technologies is the Authorised distributor of the mixing technology, and we take care of the from Import to commissioning.