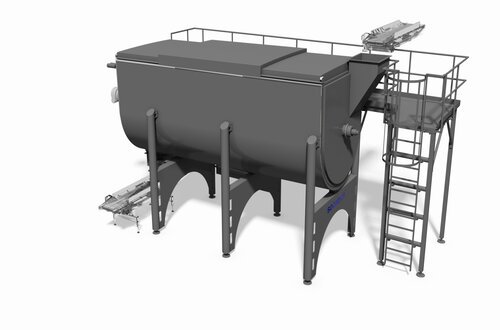

Continuous Mixing Equipment

Efficiency, consistency, and quality are critical for success in the industrial baking and food processing sectors. Batch mixing has long been the standard in the industry, but as production demands rise, businesses are searching for more reliable and efficient options. In this case, continuous mixing equipment is revolutionary for bakers, snack manufacturers, and other food producers.

Kiron Food Processing Technologies, Sobatech's authorized partner in India, makes these cutting-edge Continuous Mixing Equipment available to food producers nationwide. Through this collaboration, Indian food producers may increase output, maintain outstanding quality, and improve operational effectiveness.

What is Continuous Mixing

A modern approach of blending ingredients that does not include the stop-and-start nature of batch mixing is continuous mixing. Continuous mixing ensures a steady, uninterrupted flow in which raw materials are blended in real-time as they move through the system, as opposed to preparing components in separate batches.

This unique process gives you more control over ingredient integration, hydration, and dough development, resulting in unrivaled homogeneity and accuracy in the finished product.

Why the Shift from Batch to Continuous Mixing

For years, batch mixing has been the preferred procedure among food makers. While successful, it has significant limitations:

Extended processing times.

Inconsistencies between batches.

Increased labour and operating expenditures.

Continuous Mixing Equipment is altering the industry by providing a consistent, regulated, and completely automated option that assures greater efficiency, quality, and cost savings.

Why Food Manufacturers Are Making the Switch

Increased Efficiency

No downtime between batches ensures consistent production flow.

Consistent Quality

Eliminates fluctuation between batches for a uniform end product.

Reduced Waste

Proper ingredient management reduces material losses.

Reduced Labor Costs

Less manual involvement results in lower labour costs.

Improved Scalability

Ideal for high-volume production operations.

How Continuous Mixing Works

Precision Ingredient Feeding

The first stage in continuous mixing is to automate component dosage. Unlike batch mixing, which involves measuring materials individually for each batch, Continuous Mixing Equipment assures a consistent and regulated flow of components, eliminating weighing mistakes and lowering material waste.

Continuous Dough Hydration and Development

One of the most important parts of mixing is optimum hydration and dough development. The sobatech technique provides an even distribution of components and consistent gluten formation in bread doughs. Precision hydration prevents dry or too moist dough.

Inline Processing and Real-Time Quality Control

Unlike batch systems, which require periodic quality checks, continuous mixing equipment measures quality in real time. Advanced sensors and automation guarantee that every gram of dough adheres to rigorous quality requirements.

Seamless Transfer to the Production Line

Once the dough has reached the desired consistency, it is immediately moved to the next step of production, sheeting, shaping, or baking to provide a seamless, uninterrupted workflow.

Applications of Continuous Mixing Equipment

Sobatech's technology is not confined to a certain food category. It is built for flexibility and adaptability, making it excellent for a variety of culinary products:

Bread and Bakery Products

From sandwich loaves to artisan bread, Sobatech's Continuous Mixing Equipment guarantees proper hydration and dough development, resulting in dependably better-baked items.

Snack and Crackers

To get the desired crunch and texture, snack manufacture requires exact dough consistency. Sobatech's method offers uniform sheeting and shaping, resulting in fewer product faults.

Pizza dough and flatbreads

Continuous Mixing Equipment ensures the right flexibility and moisture for pizza bases, resulting in an optimal rise and texture.

Cookies, cakes, and pastries

For soft, sweet baked items, an equal mixture of flour, fats, and liquids is essential. Sobatech's technology offers a smooth and consistent texture in cakes, biscuits, and pastries.

Alternative Doughs

With the rise of customized diets, producers require equipment capable of handling complex compositions. Continuous Mixing Equipment offers constant quality for gluten-free, high-protein, and keto-friendly doughs.

Key Features of Continuous Mixing Equipment

Fully automated system

Sobatech's technologies require minimum human intervention, which reduces labour expenses and human error.

High capacity and scalability

Continuous Mixing Equipment can manage large-scale production without interruption, making it an excellent alternative for expanding firms.

Precise Ingredient Control

Advanced dosing technology guarantees that the right amount of each component is administered, resulting in consistent product quality.

Improved dough development

Optimal gluten development and consistent hydration improve the texture, flavour, and shelf life of baked products.

Promotes energy and resource efficiency

Continuous Mixing Equipment reduces waste and improves energy efficiency, making it a more environmentally friendly alternative to batch mixing.

Why Choose Kiron Food Processing Technologies

Kiron Food Processing Technologies, the exclusive distributor of Sobatech's Continuous Mixing Equipment in India, provides food businesses with access to cutting-edge European technology and local assistance.

Key Benefits of Working with Kiron Food Processing Technologies

Our services include expert consultation, local support, and access to global innovations for food processing.

The Future of Food Mixing is Continuous

As food production advances, the desire for speedier, more consistent, and cost-effective solutions increases. Sobatech's continuous mixing equipment, currently accessible in India through Kiron Food Processing Technologies, is setting the standard.

Why Make the Switch

Consistent quality - No changes between batches.

Improved efficiency - Increased productivity with little downtime.

Cost savings through reduced labour and ingredient waste.

Improved food safety with less contamination hazards.

Scalability and Flexibility - Adaptable to many food businesses.

Whether you make bread, snacks, pizza dough, or specialized baked items, switching to Continuous Mixing Equipment with Sobatech may transform your production process by saving time, minimizing waste, and assuring high-quality results.

Now is the moment to learn about Sobatech's cutting-edge continuous mixing equipment, which is supported by Kiron Food Processing Technologies. The future of food processing is continuous; are you prepared to make the transition?