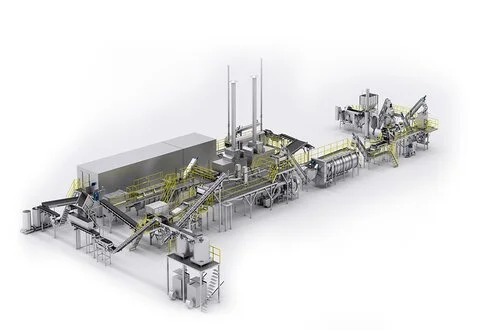

Potato Flakes Production line

A French fry line is frequently put beside the second setup in a Potato flakes production line. The product is converted into a certain quality of flakes using rejects from the French fry line, which are often off-grade potatoes, slivers, nubbins, and strips with colour problems. This strategy is an excellent way to increase the processing facility's total yield in terms of potato utilization.

Potato flakes are dried mashed potato bits that are flat. These flakes are the primary ingredient in store-bought pre-mashed potatoes, as well as commercially accessible items such as instant mashed potatoes, croquettes, pasta, and manufactured snacks.

They thicken creamy frozen desserts, gravies, and chocolate milk as a thickener. They prolong the shelf life of baked foods, much like other dehydrated potato products.

Potato flakes are a preserved form of potato that may be used as a simple replacement for cooked potatoes. Flakes have excellent rehydration properties, and the finished result resembles mashed cooked potatoes.

Potato flake is perhaps the most widely used dried potato product. Potato granules (Produced using a different drying procedure that preserves potato cells) and potato flour (Milled from potato flakes) are other comparable goods.

Potato flakes are processed into a significant food ingredient with many uses. They are now an extremely cost-effective component of recipes for end products such as stackable chips, extruded snacks, baby food, bread, and pancake mixes, formed meat products, and even non-food applications like plastics. Potato flakes are processed into a widely used food ingredient with many applications.

Process Of Potato Flakes Production line

The first system is intended to convert lower-quality potatoes that have been particularly sourced for flake production. In this case, potatoes are rinsed and stones are automatically removed before the product is peeled, either using steam or abrasive peeling, depending on capacity.

Before moving on to the heating section of the potato flakes production line, the product is size-reduced utilizing specially manufactured cutters.

What would have previously been dumped as rubbish has now been transformed into a product. Depending on the type of flake required, the cut product or rejects from another manufacturing line are blanched, chilled, and cooked or simply cooked. The cooked potato is turned into a mash, which is then transported and distributed uniformly over the flake drum.

In foreign nations, the Potato Flakes Production Line is expected to be fed with potatoes in bulk boxes containing one tonne of content each; however, in India, the potatoes would be delivered in gunny bags or loose potatoes in carts. The product is brought into the potato flakes production line by tipping the bags into the elevator or straight into the dosing hopper.

An inclined belt elevator transports the product to the cyclone de-stoner. The product enters the cyclone de-stoner in a spiral water movement, where stones and heavier particles fall against the stream into the stone collecting chamber. The potatoes have sunk to the bottom of the drum washer. The stones are either continually removed by belt or must be removed by hand now and then.

The dry matter content of the raw material must be as high as possible while making flakes from potatoes. Drying potatoes with a low dry matter content takes too much energy and results in a worse final product. As a result, a density separator should be installed in the potato flakes production line between the washer and the peeler.

All potatoes having a lower dry matter content than set will be removed by this Potato Flakes Production line unit. Floating debris will be removed from the cable as well. Normally, potatoes will have a sufficient dry matter content, and procurement will take place following quality testing at the farm level or from farms that the firm has contracted to grow.

The mash is distributed uniformly across the heated surface of the drum using applicator rollers on the drum. The liquid from the potato is transported rapidly and efficiently. off, leaving an almost dry flake sheet.

The humidity is high. as the flake is being swept away as vapour by extraction fans pre-broken into transportable chunks and sent to the location Area for packing. The flake is milled to the appropriate size. before it is wrapped in a number for the end-needs user's a variety of methods, based on the end user's preferences and requirements.

The potatoes are boiled and mashed before being shredded with rollers on the surface of a drum. The mashed potatoes are quickly dried to the required moisture content and then the dried layer of mashed potatoes is removed from the drum. The flakes are crushed in a mill sieve and then packaged.

The texture of the reconstituted product is kept firm by blanching, subsequent cooling, and the inclusion of an ingredient, a monoglyceride emulsifier, even though many of the potato cells are broken open during manufacture.

These flakes are the main ingredient in mashed potatoes sold in supermarkets and are also used in a variety of other foods. The starch retains a lot of absorbencies. Flakes are the only type of dried potato that can be quickly reconstituted with cold water, which is why they are used in so many culinary products.

In the potato flakes production line, mechanical potatoes are placed in a machine that uses flotation to separate them from rocks or sand in the batch (potatoes float, sand sinks). Even a single stone in the middle of potatoes can seriously damage the potato flaking machine. Steam.

After peeling, the potato skins are separated and cleaned before passing through a quality control table. After a visual quality check, the potatoes are cut using hydraulic equipment known as a hydro cutter, and the cut potatoes are metered. in a blancher that pre-cooks them. Sliced potatoes are cooled in a spiral cooler after cooking. The emulsion is formed by heating, cooling, and adding a monoglyceride emulsifier.

Due to the small capacity of the drum dryer, two or more are running simultaneously in many lines. There are three dryers in this potato flakes production line. Once the layer of mashed potatoes has dried, it is scraped off the drum and passed through a tube to a mill screen; There are three on this potato flake production line. This separates the flakes into smaller pieces. The flakes leave the mill sieve and go directly to the packaging plant.

Cooking | cutting | blanching

The product is gathered in a vertical screw and then sent to a bunker with a dosing screw. The product is brought to the weigh belt by the dosing screw, which is used to set the line capacity based on the dry matter content of the raw materials. The product is quickly fed into the slice cutter thanks to the weigh belt.

The potatoes are sliced into 10 to 15-mm thick slices by the cutting machine of a Potato flakes production line. For the smaller potato flakes, there are two ways to remove the free starch and tiny cutting threads. The usage of a sliver remover with a spray bar with water above to remove the starch the little bits are falling between the rolls is an excellent alternative for potato flakes production line.

Drying

In mixing tanks of a Potato Flakes production line, the additives are produced and pumped to the feed screw, where they are directly combined with the product. The mash is supplied to the drum, which is straight on in the event of one drum; in the case of two drums, the dividing screw has an aperture with a moveable dividing valve in between,

which is controlled by two measurement units in the drum dryer feed screw. This is done in the same way for a three, four and six-drive line. The potato mash is delivered to the drum dryer via a screw at this point. The potato mash is distributed across the width of the dryer in the drum dryer.

Our Principal

Kiron Food Processing Technologies, in collaboration with Tummers, has amassed a wealth of knowledge about potatoes as a natural product and the best methods for treating them over the years (Potato Processing). To produce effective and stable process lines, we combine the most advanced down-the-line innovations.

Every one of our devices is designed, built, and introduced by us. We also provide expert training to your employees so that they can operate our machine lines with ease and be prepared to keep up with them.

Kiron Food Processing Technologies is a market leader in potato flake machinery in India. We define the Potato production process stages for these potato flakes production lines, which include the manufacturing of potato purée and potato starch, according to your preferences and requirements as a client. Each machine is nurtured in-house by our Principal Tummers.

We then put them up in perfect sync with one another at that moment. As a result, we can ensure that our user-friendly flake lines perform optimally at the lowest possible cost. All potato processing procedures are completed with ease, including destoning, washing, peeling, chopping, cooking, mashing, drying, granulating, and packing.