Sleever Solution

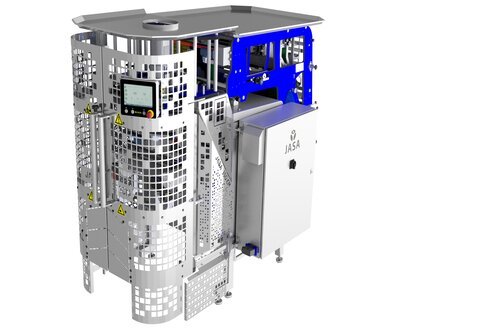

The state-of-the-art Sleever Solution is a one-stop shop for all of your trays. The Sleever Solution processes up to 100 trays per minute, has a fast changeover time of fewer than five minutes, has a sanitary design, and is simple to run.

The Sleever is a small, plug-and-play machine that can be integrated into any packaging line. Correct packaging is critical for enterprises in the fruit and vegetable industry since it affects the processing and looks of the products, as well as consumer loyalty. More and more novel packaging options are being introduced to the market for this reason.

Sleeves are 360-degree printed film pieces that shrink with heat or steam to fit around a variety of container shapes. They remove any white space, allowing your brand's art and name to take centre stage, if not the entire stage.

They also let your packaging's form show through, embracing the curves in a manner that a typical label may not. Shrink sleeves provide the added benefit of making your product recyclable, lowering your carbon footprint.

What is a Sleever Solution Machine

The Sleever Solution machine is designed for food companies that need a machine that can quickly switch from one tray/sleeve combination to another. The square meter compact design, as well as the different modular input and output systems, make it simple to integrate into current manufacturing lines.

The Sleever customizes a tray by wrapping it in a pre-folded, pre-glued sleeve. Rectangular, round, oval, and square trays, bowls, and cups with a lid, a top seal, or a flow pack are placed in 2- or 3-sided closed cardboard sleeves.

The Sleever Solution machine was created by getting back to the basics: how to combine simple operations with quick changeover times. The Sleever solution machine adds a personal touch to a tray by wrapping it in a pre-folded, pre-glued sleeve.

A tray and or a cup with a cover, a top seal, or a flow pack can be used. Trays can be formed of a variety of materials, including plastic, aluminium, cardboard, foam, and so on, as long as the packing is sturdy enough. The sleeve can be closed on two or three sides and wrapped around the tray's whole length.

How can you persuade the sleever to work as many hours as possible at the end of the day

Following the evaluation of numerous approaches, it became evident that shifting from one sleeve to another had to be as simple as "changing the sleeve." This was accomplished by making the Sleever tape the machine's heart. Every sleeve has its cassette, which is created to order. The width of the tray guiding system is automatically adjusted while changing the cassette, thanks to the auto-tracking technology.

The whole Sleever Solution is switched from one set of trays and sleeves to another in less than 5 minutes. Because of its small size, the Sleever Solution machine is simple to integrate into an existing manufacturing line. Various modular de-nesters, lid placers, and in- and outfeed units are available depending on the setup. These are readily connected to the sleever and allow you to distribute trays from a packing machine with a single lane outfeed into a double lane sleever, among other things. After a double-lane sleeve, trays may be rotated into the proper position, and packages can be returned to a single-lane outfeed.

APPLE, KIWI, AND TOMATO TRAYS AND SLEEVES

The Sleever solution customizes a tray by wrapping it in a pre-folded and pre-glued sleeve. Trays that are rectangular or square are put in two-sided cardboard sleeves.

The clever design allows the apples, kiwis, and tomatoes to remain visible in the packaging while preventing them from being removed without breaking the sleeve. A label connected to the bottom of the tray secures the sleeve to the tray. In addition to the barcode, this label can be used to store product information. Last but not least, the sleeve's design includes a handle, making the box easy to transport.

Because the influence of changeover periods on production is reduced, the user may process many more trays at the end of the day than with a traditional manufacturing method. Most sleevers need at least a half-hour of switching time, however, the sleever Solution lowered this to under 5 minutes.

The flexibility of human sleeving, which can cost anywhere from 1.5 to 3 FTE per line, is preserved when employing the sleever solution, but the production of automation sleeving is far greater. As a result, the payback period is quite quick.

Benefits of Sleever Solution Machine

INCREDIBLY QUICK

The sleeve can be made to keep fruit that has been sorted by size in place. The Sleever solution machine comes with one or two belts, a bypass or rejects station and a label applicator as an option. With the single belt model, the Sleever can process up to 50 trays per minute, and with the two belt model, up to 100 trays per minute. The gross capacity will vary based on how your product is packaged, the configurations of your packing line, the thickness of the trays and sleeves utilized, and the product's infeed speed.

STATE-OF-THE-ART TECHNOLOGY

The Sleever solution machine is completely servo-driven, and it was designed to use as few moving components as possible. This, in combination with dependable PLC control and a connected Smart display, guarantees a high degree of operational convenience: pre-programming and starting "at the touch of a button."As a consequence, a sleever has been created that combines ease of use with minimal maintenance expenses. Security screens and safety sensors are installed on all doors and moving parts, and the machine is manufactured by CE safety rules.

Our Principal

Kiron Food Processing Technologies, in collaboration with Jasa Packaging Solutions, offers a comprehensive Sleever solution. We are the global leader in creative high-added-value labelling solutions, providing companies with a variety of package options including decoration, personalization, tamper-evident seals, sales promotion, information, and traceability.

JASA Packaging Solutions stands for packaging technology innovation, quality, and flexibility. Vertical packaging machines, Sleevers, and entire weighing and packaging lines are some of our specialities. For more than thirty years, producers and packers of various types of food products throughout the world have relied on our knowledge 24 hours a day, seven days a week.