Vegetable Processing Machine

The key to a well-designed Vegetable Processing Machine is that it must be able to run for as many months as feasible throughout the year. This means that the facilities, buildings, material handling, and equipment must all be properly interconnected and coordinated to handle as many products as possible at the same time, while the equipment must also be versatile enough to handle a variety of products without major modifications.

A typical processing centre or factory should process four or five different varieties of vegetables collected at various periods throughout the year. Dried finished goods, juices, pickles, tomato juice, ketchup and paste, jams, jellies and marmalades, and semi-processed fruit products must all be handled by the vegetable processing machine.

Agriculture is the backbone of the economy in underdeveloped countries. As a result, it should come as no surprise that agriculture and associated sectors account for a significant amount of their production. Vegetable Processing is one of the most significant forms of agriculturally based activities. Vegetable Processing Machines, both existing and proposed, are designed to address a particularly specific development need.

This means that the producer suffers significant losses as a result of limited demand, poor infrastructure, bad transportation, and the perishable nature of the crops. The loss is significant during the post-harvest glut, and part of the product is typically given to animals or allowed to decay.

Vegetable processing Machines also seek to replace imported items such as squash, yams, tomato sauces, pickles, and other condiments, as well as gain foreign cash by exporting completed or semi-processed goods.

Processing Planning

Due to irregular supply, even established fruit and vegetable canning plants or small and medium-scale processing centres lose a lot of money. The producer may prefer to sell his vegetables directly to the consumer on the open market, or the produce may not be of high enough quality to prepare, even if it is edible.

As a result, processing capacity will be significantly underutilized. The primary goal of a vegetable processing machine is to provide consumers with wholesome, safe, nutritious, and palatable food throughout the year.

To produce a wide range of goods in a variety of weather and temperature circumstances, advanced preparation is required, with each product having its own set of production and packaging formulas. The initiatives should culminate in a well-managed processing unit with a reduced starting outlay.

An integrated operation results from a unit that is well-designed and where one necessity is related to another, as well as a thorough costing study. When the planned output is not particularly large and is primarily aimed at fulfilling the needs of the local market, a reasonably simple processing unit may be necessary instead of too complicated technology.

Small Scale Vegetable Processing Machine

Small-scale farmers do this for personal use or sale in surrounding marketplaces. Processing involves little investment in this Vegetable Processing Machine method, however, it is time-consuming and tiresome. Small-scale processing met the demands of rural and urban people until recently. However, with the growth rates of population and urbanization, as well as their more diverse dietary demands, more processed and diverse forms of food are required.

Intermediate Scale Vegetable Processing Machine

A set of small-scale processors pool their resources in this scale of processing. Individuals can also participate in this. Vegetable processing is based on the technique employed by small-scale processors, with variations in equipment type and capacity.

The raw ingredients are often cultivated on-site by the processors or obtained on a contract basis from other farmers. To ensure raw material availability and save transportation costs, these functions are frequently placed on the manufacturing site. This technology of vegetable processing can supply large volumes of processed goods to metropolitan regions.

Benefits of Vegetable Cutting Machine

Large Output

The Vegetable Processing Machine is made to chop a variety of stems, leafy, and root vegetables, as well as fruits and other foods. It could produce more than 3000 servings each hour at a rate of more than 1000 kg. Similarly, it is a useful gadget that allows you to swiftly and accurately chop a variety of vegetables, fruits, and ingredients.

Various Vegetable Processing Techniques

The Vegetable Processing Machine can achieve accurate thickness and diverse forms by changing many cutting discs. For diverse root, foliage, and stem vegetables such as potato, green scallion, leek, celery, cabbage, carrot, potato, onion, cucumber, mushroom, onions, and so on, it could complete the same process with even cubes, threads, slices, and strips. It might also be used to charge for the cutting of fruits such as apples, pears, and bananas.

Operational Safety

Our multifunctional vegetable processing machine will solve this problem. You cannot open the lid while the machine is operating since all of the blades are hidden within the inner structure; once the cover is opened, the machine will immediately stop. In case of an emergency, simply hit the emergency button, and the machine will shut down.

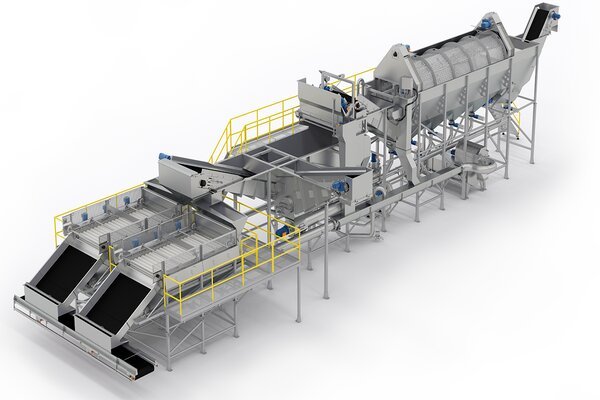

Our Principal

Kiron Food Processing Technologies with Tummers BV offers a complete Vegetable Processing Solution For your Business. Tummers BV was founded in 1976 as an engineering company and the maintenance partner for the flourishing potato industry in the province of Zealand. Tummers Food Processing Solutions has since become a leading manufacturer of machines, machine parts, and complete production lines for potato and vegetable processing