VERTICAL PACKING MACHINE

A Vertical Packing Machine is a vertically oriented pouch forming and filling equipment. It is mostly used for industrial packaging and processing, since it provides a more convenient and effective method of automatic packaging, saving a significant amount of time and money.

Vertical Packing Machines come in a variety of styles. VFFS is one of them, and it combines the functions of pouch creation, filling, data printing, and accounting. With servo motor film pulling and automated bias correction during film pulling, the VFFS machine runs smoothly. The pneumatic cylinder with dependable movement is used for both horizontal and vertical sealing.

Vertical Packing Machines a superb multi-function packaging equipment for many sectors, such as snack food, sugar, shampoo, pet food, coffee, tea, yeast, feedstuff, fertilizer, and so on, due to their compact design and excellent electrical control.

The Vertical Packing Machine has been upgraded to accommodate multiple bag types. It may build a variety of pouches with the addition of additional gadget gadgets. There is a pillow pouch, gusset sachet, perforated with hang-out for shelf stick displaying, and quad seal, for example. Furthermore, the filler, also known as a filling device, is an excellent partner for this vertical form fill seal machine. Weigh filler, volumetric cup filler, auger filler, pump filler, and other similar devices.

The Vertical Packing Machine creates plastic bags and stand-up pouches from a flat roll of film while simultaneously filling and sealing the bags with goods. This packaging technology may be used to package both solids and liquids.

A Vertical Packaging Machine is often filled with a continuous flat roll of plastic film that has been labelled and the artwork is attached to the exterior or inside of the film. While plastic is the most prevalent packaging material in the food business, the technique may also be utilized to create continuous metalized foil/film, paper, and fabric product containers by adjusting the edge sealing/seaming procedures.

Vertical Packing Machines employ roll stock, which is a single sheet of film material rolled around a core. The film web refers to the continuous length of packing material. Polyethylene, cellophane laminates, foil laminates, and paper laminates are all examples of this type of material. The film roll is put on a spindle assembly in the machine's back. The film is normally taken off the roll by film transport belts, which are positioned to the side of the forming tube, which is placed at the front of the machine, while the Vertical packing machine is in operation.

Components of the Vertical Packing Machine

Film Pulling System

An unwinding roller and tensioner are used in this mechanism. There was a long, long film that rolled in a roll and was referred to as the roll of film. The film for the Vertical packing machine is often laminated PE (polyethene), PET, paper, and aluminium foil. The roll stock film will be loaded into the VFFS machine's unwinding roller back. The film on the reels of the film pulling system is driven and pulled by servo motors. They completely complement each other and pull smoothly and dependably in continuous action.

Printer

The photo-eye will capture the deep colour tag written on the rollstock of the film after the film drawing to the spot that the printer (optional). The film will then be printed with the date and production batch code. The printer normally comes in two varieties: standard, which uses a black ribbon, and TTO, which uses a white ribbon (Thermo Transfer Overprint)

Pouch Formers

After the film has been printed, it is transferred to the bag forming. It's similar to a collar of human clothing. This bag forming produces a wide assortment of bags or pouches. Bag formers of various sizes can be used to create various sizes of bags. If different sizes of bags are to be packaged, the forming cube must be changed. It merely takes a few minutes to switch it around. The bag former features a filling function in addition to its bag-forming function. Through it, the bulk material will be poured into the bag. The bag formed is composed of stainless steel and is therefore food-safe.

Filling & Sealing Machine

The Vertical Packing Machine comes with two sets of sealing devices. The first is a vertical sealer, whereas the second is a horizontal sealer. It may create a vertical pattern with two vertical sealing jaws. When you use a single vertical sealer and push on the bag former, a flat or net pattern is created. Variable sealing patterns are possible with various types of sealers. Following the sealing of the bags, the weighted bulk items will be placed inside the bags.

Pouch Cut

There is a cut inside the horizontal sealers of the Vertical packing machine. After sealing, it slices the edge of the bag on the flat bottom. Let's move on to the next vertical packing machine activity.

Control Cabinet

A control cabinet is attached to the side of the vertical packing machine. It houses all of the electrical components. PLC, contactor, servo motors, pneumatic cylinders, solenoid valves, PLC expand mode, and low-pressure electrical components The HMI (Human-Machine Interface) is located on the cabinet control panel's outside.

How does a vertical packing machine work

The film in a Vertical packaging machine reaches the back of a long hollow conical tube known as the forming tube. When the plastic's centre is close to the tube, the film's outside edges generate flaps that wrap around the conical-forming tube. The film is pushed downward around the outside of the tube, and a vertical heat-sealing bar clamps onto the film's edges to form the "fin Seal," which bonds the film by melting the seam edges together.

A horizontal sealing bar generates the "Bottom Seal" by clamping over the bottom edge of the tube, glueing the film together, and cutting off any film below to begin the bagging process. This sealing bar can be set at a fixed height, which is referred to as an intermittent sealing procedure. A sealing bar that travels down with the bag when sealing is included in faster systems.

In a Vertical packing machine the product is either pre-measured by a multi-head weighing system or the sealed tube end is dropped onto a precision weighing platform, and the product to be bagged is distributed through the bag's long conical tube in the middle. When the gross weight of the product-filled bag is achieved, the filling stops and the horizontal sealing bar seals the top of the bag, producing the bottom of the next bag above at the same time.

This bag is then removed from the tube and sealed, ready to move on to the product boxing and shipping operations. The bag can be filled with air from a blower or an inert gas source, such as nitrogen, during the final packing process. Inflating the bag reduces the crushing of fragile articles like potato chips, while inflating with inert gas drives away oxygen and slows the growth of microorganisms that would damage the product. Other product finishes, such as hole punching for retail hanging racks, will be completed concurrently with or shortly after the "Top Seal."

Material feeding and bag/pouch cutting can be determined either by pouch length or by indexing to an eyespot (photo registration mark) detected by a visual sensor. While single web systems are common for food applications, IVD and medical device goods frequently use the twin web four-side seal system. The horizontal form-fill-seal machine, which requires more floor area than a vertical system, is closely comparable.

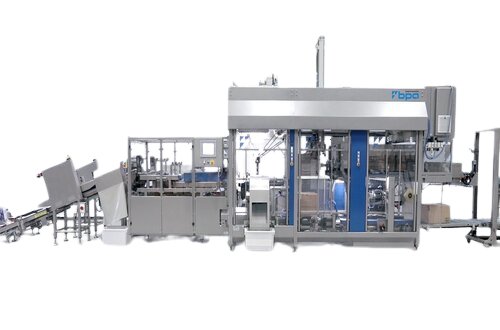

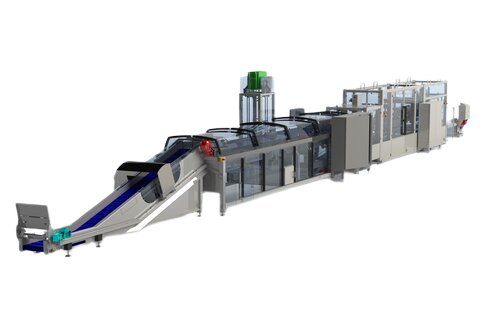

Our Principal

Blue Print Automation in association with Kiron Food Processing Technologies offers a complete Vertical Packing Machine for your Business.