Rotary Drum Mixer

Kiron Food Processing Technologies provides Rotary drum mixers for mixing and processing fine powders, granulates, and natural products. LINDOR rotary drum mixers swiftly combine and handle huge quantities in an efficient, dependable manner that consumes little energy. We never use shear force to stress or heat particles in our rotary drum mixers. Gravity ensures that every particle maintains its original size, shape, and qualities.

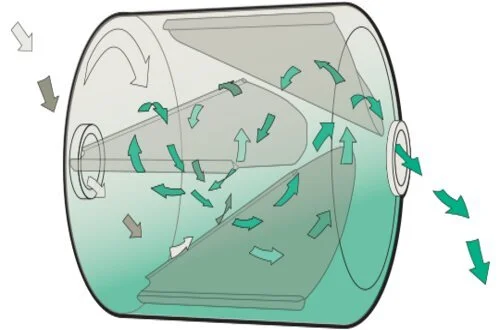

This is how we optimize the performance of your chemical, polymer, and mineral goods. The LINDOR rotary drum mixing method is based on the free flow of product through a relatively slow rotating vessel outfitted with appropriately shaped and positioned vanes. The product is introduced through the intake located in the vessel's middle line.

Rotation and gravity gently spread the product at random. Backflow occurs when the product accumulates on the output side. These flows combine to provide a mild mixing motion, which results in a homogenous product in around 1-5 minutes. After opening the exit valve, the product departs the rotating drum mixer in a couple of minutes, driven gently by the vanes. The rotating drum mixer empties itself fully.

Advantages of Rotary Drum Mixer

Rotary drum mixers offer a range of advantages, making them suitable for various industrial applications, particularly in the mixing of sensitive and fragile products. Here’s a detailed explanation of each listed advantage:

Excellent Homogeneity in a Short Mixing Cycle

Rotary drum mixers are designed to provide uniform mixing of materials in a relatively short period. The tumbling action of the drum ensures that the materials are continuously lifted and dropped, which promotes thorough blending. This mechanism ensures that all components are evenly distributed, achieving high homogeneity quickly.

No Breaking and Frictional Heat

The gentle tumbling action of the rotary drum mixer prevents excessive mechanical stress on the materials. This is particularly important for fragile or sensitive products, as it reduces the risk of breaking or degradation during mixing. Additionally, the low-intensity mixing process minimizes the generation of frictional heat, which can be detrimental to heat-sensitive substances.

Minimum Segregation

The rotary drum mixer's design helps to reduce segregation, where components of a mixture separate based on size, shape, or density. The constant movement and rotation ensure that particles remain evenly dispersed throughout the mix, maintaining consistency in the final product.

Suitable for Sensitive and Fragile Products

Due to the gentle mixing action, rotary drum mixers are ideal for handling delicate materials that could be damaged by more aggressive mixing methods. Pharmaceuticals, food products, and certain chemicals that require careful handling benefit from this type of mixer.

Quick and Easy to Clean

Rotary drum mixers often feature smooth internal surfaces and easy access points, making them simple to clean. This is particularly important in industries where cross-contamination between batches must be avoided, such as in pharmaceuticals and food processing. The ability to clean the mixer quickly and thoroughly enhances operational efficiency and product safety.

Very Low Energy Consumption

The design of rotary drum mixers allows for efficient mixing with minimal energy input. The slow and steady rotation requires less power compared to more intensive mixing equipment, which can lead to significant energy savings over time. This makes the rotary drum mixer an environmentally friendly and cost-effective option.

Low Maintenance

Rotary drum mixers are relatively simple in construction with fewer moving parts compared to other types of mixers. This simplicity translates to lower maintenance requirements and costs. The robust design ensures durability and long service life, reducing the need for frequent repairs and part replacements.

Horizontal Construction

The horizontal orientation of the rotary drum mixer contributes to its stability and ease of use. This design is often more accessible for loading and unloading materials, and it can be integrated into existing production lines with minimal disruption. The horizontal layout also enhances the efficiency of the mixing process by ensuring the even distribution of the materials.

Variable Batch Size

Rotary drum mixers are versatile in terms of the batch sizes they can handle. They can efficiently mix both small and large quantities of materials, making them suitable for various production scales. This flexibility is advantageous for manufacturers who need to adjust production volumes without compromising on mixing quality.

Options and features of Rotary Drum Mixer

A rotary drum mixer is a versatile piece of equipment used in various industries for mixing powders, granulates, and other materials. Here are detailed explanations of its features and options.

Liquid Injection to Coat or Impregnate Powders and Granulates

This feature allows for the precise addition of liquids into the mixer, ensuring that powders and granulates can be evenly coated or impregnated with the liquid. This is useful in applications such as pharmaceuticals, food processing, and chemicals where ingredients need to be uniformly distributed.

Continuous Mixing for Uninterrupted Product Flow

Continuous mixing ensures that materials are mixed without interruption, which is crucial for processes that require a constant output. This is particularly beneficial in large-scale production environments where downtime can be costly.

Heating and Cooling with Steam/Water/Oil Jacket During Processing

The mixer can be equipped with a jacket that allows for heating or cooling of the materials inside the drum. Steam, water, or oil can be circulated through the jacket to control the temperature, which is important for processes that require precise thermal management, such as chemical reactions or food processing.

Cryogenic Mixing Using Liquid Nitrogen at Controlled Temperatures

For materials that need to be mixed at very low temperatures, cryogenic mixing using liquid nitrogen is an option. This is essential for handling temperature-sensitive materials or for processes like grinding brittle materials into fine powders.

Air Drying/Heating/Cooling

Air can be used to dry, heat, or cool the materials inside the mixer. This feature is particularly useful for drying wet materials, cooling hot materials, or heating materials to facilitate chemical reactions.

Retractable Inlet/Outlet QSR (Quick Service Release)

This feature allows for quick and easy access to the inlet and outlet of the mixer for maintenance and cleaning. Retractable inlets and outlets can improve operational efficiency by reducing downtime.

ATEX 20/21/22 (Powder, Dust) and 0/1/2 (Vapor, Gas)

ATEX certification ensures that the mixer is safe to use in explosive atmospheres. Zones 20, 21, and 22 are related to explosive dust, while Zones 0, 1, and 2 are related to explosive vapors and gases. This is crucial for industries such as pharmaceuticals, chemicals, and food processing, where dust or gas explosions can be a significant risk.

Pressure and Vacuum

The ability to operate under pressure or vacuum conditions expands the range of processes that can be performed with the mixer. Vacuum mixing can remove air and gases from the mixture, which is beneficial for certain chemical and pharmaceutical processes, while pressure mixing can help in reactions and improve the penetration of liquids into solids.

WIP/CIP (Washing In Place/Cleaning In Place)

WIP and CIP systems allow the mixer to be cleaned without disassembly. This is particularly important in industries with strict hygiene standards, such as food and pharmaceuticals, where contamination must be minimized.

Extra Large Easy Opening Doors

Large doors facilitate easy access for cleaning, maintenance, and inspection. This feature reduces the time and effort required to maintain the mixer, ensuring that it remains in optimal working condition and minimizing downtime.

Each of these features enhances the functionality and versatility of the rotary drum mixer, making it suitable for a wide range of industrial applications.

Rotary drum mixer for food industry

For food, hygienic design and ease of washing are critical. The weld quality and surface polish receive special attention and effort. All metal components that come into touch with the product are composed of stainless steel (AISI 316L or AISI 304). All other components are created from FDA-approved materials. On request, the frame and other components can be constructed of stainless steel. To make cleaning and maintenance even easier, the rotary drum mixer can be supplied with a retractable inlet and outlet - QSR.

We have designed rotary drum mixers for major food, tea, and dairy processing companies across the world. We assisted a multinational maker of savoury snacks in improving the flavour of their gently spiced goods while reducing waste.

We assist customers in mixing a wide range of ingredients, including morning cereals, tea, milk powders, baby food, infant cereals, instant coffees, snacks, nuts and dried fruits, and baking powders. Our rotating drum mixers can handle anything fast, from tiny to huge quantities in a clean atmosphere, while improving the purity and flavor of each component.

Rotary drum mixer for fine chemicals and plastics industry

Chemical processing frequently requires the use of bigger mixers. Our rotary drum mixers may be delivered in batches of up to 25 m3 (15 tons of product). The rotating drum mixers can be fitted with a double wall for water or steam heating and cooling. Heating/cooling/drying can also be achieved by circulating air through the tank.

Our rotary drum mixers are custom-made to meet the particular demands of cosmetics and chemical customers worldwide. We also help catalyst companies impregnate and dry their carrier material, increasing the efficiency and safety of their manufacturing process and products.

Whether you need to make detergent powders, catalysts, ceramic powders, polymer compounds, engineering plastics and MIM granulates, raw materials for electronics like battery powders, or combine metal powders, the quality of your goods is always in our capable hands.

Rotary drum mixer for pharmaceutical industry

We have custom-made rotary drum mixers for major pharmaceutical companies all over the world. We aided a major maker of prescription drugs in drying its API at a low temperature under a vacuum without destroying the powder's delicate structure, hence enhancing the product. Whether you need to manufacture prescription medications, generic meds, clinical nutrition powders, or herbal medicines, we will always ensure the quality of your goods.

OUR PRINCIPAL

Lindor Gentle Touch Technology is intended for blending tiny powders, granules, and natural ingredients. The main benefit is its ability to achieve high uniformity fast while maintaining the product's quality. Our delicate mixing method allows you to efficiently generate high-quality goods. Kiron Food Processing Technologies is the authorized distributor of mixing technology, and we handle everything from import to commissioning.