Automatic Packing Machine

The Automatic Packing Machine has contributed significantly to the growth of the packaging process and the development of packaging technology.

Furthermore, with the development of the market and the ever-expanding distribution network, packaging has become a must for all items.

Modern industry relies on automatic packaging equipment for speed, precision, and error-free efficiency.

Automated packaging saves money, ensures safety, and makes your products more appealing. It will also allow you to grow your business while maintaining employee safety and profitability.

Has your business outgrown manual packing methods? Are you seeking ways to increase your packing efficiency and productivity? If so, you may consider purchasing an automated packing machine.

The technology in automatic packaging machines ensures that packing mistakes are minimal. The automation permits programming so that just the specified amount of product is discharged and packaged. Sensitive weight sensors verify and monitor the packing, ensuring little waste and uniformity of quantity in each box.

Automatic packing machines are increasingly more cheap and may be tailored to meet individual packaging requirements. They are also easier to use and maintain than ever before.

You do not have to be a major corporation to purchase an automated packer. If hand packaging no longer satisfies your requirements, it may be time to invest in this sort of technology.

What’s Automatic Packing, and How Does It Work

Automatic packing is the process of putting things into cases with a machine. The machine will place the items in the case, seal them, and then release them onto a conveyor belt.

Automatic packaging machines are commonly used to pack large quantities of merchandise. They may be used to package a wide range of things, including food, drinks, cosmetics, and electronics.

There are various varieties of automatic packaging machines, each with its own distinct characteristics.

The most popular variety is the side-load packer. This machine feeds things into the case from the side with a gripper arm.

Another form of automated packer is the top-loading case packer. It inserts things into the case from the top using a product pusher.

Benefits of Using an Automatic Packing Machine

Because of their numerous advantages, automated packaging machines are popular among enterprises. Without automatic packaging equipment, businesses would have to manually pack items, which is a time-consuming and tiresome procedure.

In recent years, automated packaging equipment has become less expensive. This makes them an attractive alternative for even tiny organizations. You only need a power supply and an air compressor.

The devices can also be modified to fit your unique company requirements. They can be configured with a number of functions, including automated product feeds and separators. The chips packers may also be set to pack items into a range of case sizes.

Furthermore, if your company packs a variety of items, you may get a machine that can pack these products simultaneously.

How to Choose the Right Automatic Packer For Your Business

Choosing the ideal automatic packer for your business might be difficult. Here are some aspects to consider while making the best selection for your business.

The kind of products you need to pack

Automatic packers can handle a wide range of products, including bottles, cans, jars, and cartons. Make sure you choose a machine that is suitable for the items you need to pack.

The Quantity of Products You Need to Pack

Automatic packaging machines have capacities ranging from a few hundred to thousands of goods per hour. You should choose a computer that can manage the specified throughput.

Your budget

Automatic packers can vary greatly in price, so determine a budget before you begin looking. You should also consider the cost of any extra equipment you may require, such as conveyors.

The Case Sizes You Need to Pack

Automatic packers may hold a variety of case sizes. Make sure you choose a machine that can accommodate the size of the cases you need to pack.

The Features You Need

Automatic packers can offer a variety of capabilities, including product collation, product orientation, and case erecting. Choose a machine that has the functionality required for your packaging application.

Tips for Getting the Most Out of Your Packing Machine

Your company's financial line is dependent on the productivity of its machinery.

To get the most out of your automatic packaging equipment, follow these guidelines:

Keep your machine clean and debris-free. This will assist in guaranteeing correct and effective packing.

Before packaging, inspect your goods to ensure that it is free of damage or defects. Damaged or damaged materials can create packaging mistakes, resulting in costly delays and production shutdowns.

Pack things in the right orientation to ensure maximum protection and stability. Incorrectly packed items are more likely to be damaged during shipping and handling, resulting in consumer unhappiness.

Select an appropriate case for your product and application. The improper case might cause harm to objects during packaging or shipping.

Maintenance and Troubleshooting Tips for secondary packing

Automatic packaging machines, like any other equipment, require regular maintenance to ensure their precision, safety, and lifespan.

Here are some recommendations for keeping your equipment functioning smoothly:

Check the infeed conveyor to ensure appropriate alignment and tension. Misaligned or slack belts might jam cases in the machine.

Inspect all case sealers and Pack-off stations to ensure good operation. If one of the stations fails to work properly, the system may experience a backup.

Ensure that all product sensors are correctly calibrated. Incorrectly calibrated sensors might lead to lost or damaged items.

To avoid the accumulation of dust and debris, clean the equipment on a regular basis.

If the machine is not working properly, you can attempt the following troubleshooting methods before calling for service:

Check the power supply to ensure the machine is properly connected and receiving power.

Check the control panel to ensure that all switches are in their right locations. Look for obstacles in the product feed or discharge chutes.

Check the product guiding rails to ensure they are debris-free.

Check the case ejector mechanism to ensure it functions properly.

If you are still having problems with your computer, contact your local service centre for help.

Bottom Line

Automatic packaging machines provide your company with a competitive advantage by enhancing production and efficiency. An automatic packing machine may assist you in meeting your packaging requirements, regardless of industry.

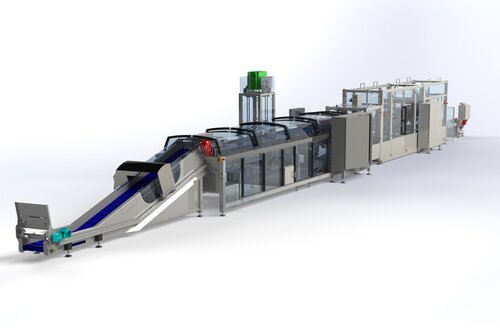

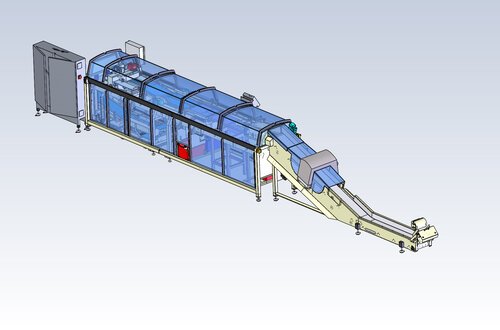

Automatic Packing Machine from Blue Print Automation

Blue Print Automation is a pioneer and leader in automated packaging equipment and end-to-end packaging solutions. BPA's unique packaging solutions for food, pharmaceuticals, and other industries are supplemented by sophisticated solutions for secondary packaging, wrapping and cartoning, bulk packaging, and more.

If you need a new machine or an entire line, or if you just want to improve your present packaging machine, contact Kiron Food Processing Technologies. Kiron Food Processing Technologies, as an industry specialist with two decades of proven experience, will give the best solution backed up by exceptional consulting and support.