Screw Conveyor

Screw conveyors, also known as auger conveyors, are industrial equipment used to move vast amounts of granular materials such as powders, grains, granules, semi-solids, liquids, and even non-flowing substances from one point to another. They improve operating efficiency by eliminating the need for human manipulation of materials. A screw conveyor's main components are a revolving screw shaft and a conveyor. As the screw shaft revolves, the material travels in a linear path. Screw conveyors can be set up for horizontal, vertical, or inclined transport pathways.

Screw conveyors are intended to accommodate different material properties. Bulk materials may be abrasive, non-free-flowing, fluidizing, hygroscopic, or toxic. Screw conveyors are used to handle items such as cereals, fertilizers, animal feed, ash, gravel, cement, and solid wastes.

The Archimedes screw, invented circa 250 BC, was the first screw conveyor. This early type of positive displacement pump was initially employed to transport water from lower places to higher irrigation channels. Archimedes screws' design and driving mechanisms have evolved throughout time to improve efficiency, durability, and speed while maintaining the original design's essential principles.

Components of Screw Conveyors

Conveyor Screw

The Conveyor Screw is a vital component of a screw conveyor since it transports particles along the conveyor. It consists of a shaft with a large blade whirling helically around it. The spiral blade is referred to as the flight. Conveyor screws function similarly to large screws, moving material by one pitch for each full revolution of the screw. The pitch is the axial distance between consecutive flight crests. As the conveyor screw spins to move the material, it remains stationary in the axial direction.

Standard Pitch Screw Conveyors

Standard Pitch Screw Conveyors have a pitch that corresponds to the screw's diameter. The screw diameter represents the radial distance between successive flying crests. These conveyors are commonly utilized in horizontal applications and inclined conveyors with angles less than 10°. They are effective in handling a wide variety of materials.

Variable Pitch Screw Conveyors

Variable Pitch Screw Conveyors have pitches that vary along the screw flight. The pitch is longer on the inlet side to make room for feed materials when they are released from hoppers, bins, or silos. Screw feeders employ variable pitch screw conveyors to manage the volumetric flow rate of material.

Short Pitch Screw Conveyors

Short Pitch Screw Conveyors have a pitch for the screw diameter. These conveyors are frequently utilized in inclined and vertical applications, as well as to move free-flowing materials without flushing.

Half Pitch Screw Conveyors

Half Pitch Screw Conveyors have a pitch that is equal to half the screw diameter. These conveyors are also used in screw conveyor applications, both inclined and vertical.

Long Pitch Screw Conveyors

Long Pitch Screw Conveyors have a pitch that is 1.5 times the diameter of the screw. These conveyors are perfect for transporting liquids, free-flowing products, and high-speed material handling tasks. They are also good at agitating the items being moved.

Double Flight Screw Conveyors

Double Flight Screw Conveyors contain two helical sets of flights along the length of the screw, which speeds up the conveying process. The flights are offset by 180°. Double flight screw conveyors, like standard pitch screw conveyors, have a pitch that corresponds to the screw diameter. These conveyors maintain a consistent material flow rate and run smoothly during transport.

Tapered Flight Screw Conveyors

Tapered Flight Screw Conveyors have a constant pitch, but the flight width gradually increases from two-thirds of the screw diameter at the intake to the full diameter at the discharge end. This design adds more room at the intake, allowing for more equal material movement. Tapered flight conveyors are a less expensive alternative to variable pitch screw conveyors, and they are especially useful for handling lumpy particles.

Mass Flow Screw Conveyors

Mass Flow Screw Conveyors use a conical screw with uniform flight pitches at the feed intake. As it moves closer to the discharge, the conical part transforms into a variable-pitch screw. They are intended to provide regular material extraction from hoppers, bins, or silos, resulting in uniform material flow. The volume of material handled gradually rises with each flight as it passes through the conveyor.

Helicoid Flight Screw Conveyors

Helicoid Flight Screw Conveyors have flights made of flat steel bars or strips that are cold-rolled into helical shapes. This procedure hardens and strengthens the material, producing a smooth flight surface. The flights have a thicker base that tapers to a narrower edge around the outside perimeter. These helicoid flights are connected to the central shaft by welding the short, separate flights together. The shaft's flights are fastened using intermittent welds at either end.

Helicoid flying screw conveyors are noted for their longevity and great load-bearing capability while being cost-effective. They are capable of handling mild to moderately abrasive materials such as limestone, cement, and fertilizers.

Sectional Flight Screw Conveyors

The discs of Sectional Flight Screw Conveyors are cut to length by a plasma, water jet, or laser cutter and pressed to create a helix or individual flight, each of which corresponds to one rotation. The sectional flight conveyor screw is built in the same way as the helicoid conveyor screw.

Sectional flights have identical material thickness throughout. There are thicker variants available, making sectional flight screw conveyors ideal for carrying extremely abrasive materials such as glass cullet and alumina.

Cut Flight Screw Conveyors

Cut Flight Screw Conveyors have notches cut onto the outside edge of the screw flight at regular intervals. These notches make it easier to mix and agitate the bulk material being delivered. This conveyor is ideal for products that tend to pack, such as hydrated lime, dry milk, and talc.

Cut and Folded Flight Screw Conveyors

Cut and Folded Flight Screw Conveyors have both notches and folds along the outside edge of the screw flight. The folds are raised above the flight's surface, and along with the notches, they slow down material flow and improve mixing. These qualities also help to aerate lightweight materials and maintain consistent temperature distribution during heating and cooling procedures.

Ribbon Screw Conveyors

Ribbon Screw Conveyors provide an open area between the inner edges of the flight and the centre shaft. These conveyors may be manufactured in either a single or double-flight arrangement.

Single Flight Ribbon Screw Conveyors

Single Flight Ribbon Screw Conveyors are often suitable for conveying sticky and viscous materials that tend to gather near the conveyor screw shaft.

Double Flight Ribbon Screw Conveyor

Double Flight Ribbon Screw Conveyors are efficient in transporting sticky substances and provide more constant material discharge. They can also be set to mix dry ingredients. In this configuration, the conveyor has an outer ribbon flight and an inner ribbon flight, each with a smaller diameter, and they revolve in opposing directions. This arrangement promotes thorough mixing by moving the material back and front within the conveyor.

Standard Pitch Single Flight Screw Conveyors with Paddles

This Screw Conveyor System uses paddles between the screw flights to gently and efficiently integrate bulk items.

Standard Pitch Screw Conveyors with Paddles

The Screw Conveyor design has adjustable paddles arranged helically along the screw shaft. Each pitch can include up to four paddles to help mix bulk materials and manage their flow. While it has the most strong mixing effect, it is the least efficient of any kind.

Screw Conveyor Handedness

The direction in which a Screw Conveyor moves material is determined by its handedness or the direction in which the conveyor screw revolves. Screw conveyors can be either right or left-handed. When rotated clockwise, a right-handed screw conveyor takes the material to the screw's end; when rotated counterclockwise, a left-handed screw conveyor accomplishes so. Reversing the screw's rotation direction also reverses the material flow, however, this is generally not recommended because material should be handled on the carrying side of the flight.

Examine the end of the screw conveyor to assess handedness. The flighting loops around the shaft clockwise in right-handed screw conveyors and counterclockwise in left-handed conveyors. Screw conveyors that are right-handed are more typically employed than left-handed ones.

Conveyor

The Screw Conveyor encloses the conveyor screw and supports the bulk material while it is moved. It can be strengthened by saddles or flanged feet along its length. A strong, detachable cover stretches over the conveyor, protecting the bulk material from contamination, dust, and any risks.

The conveyor also has access ports for feeding and withdrawing bulk materials. The conveyor intake is typically connected to additional equipment such as belt conveyors, rotary valves, and screw feeders, all of which regulate or measure the material entering the screw conveyor. These components are frequently coupled to hoppers, silos, and bins that hold bulk materials. Alternatively, the conveyor intake can be located immediately on the outflow side of the upstream processing equipment.

Screw conveyors come in numerous varieties:

U-shaped conveyor

The U-Shaped Conveyor is the most popular and versatile form of screw conveyor. It is inexpensive and has a simplistic design.

Angle Flange Conveyor

Formed Flange Conveyor

Double Formed. Flanged Conveyors

Formed Channel Conveyor with Drop Bottom Conveyor.

Flared Conveyor

Rectangular Conveyor

Rectangular Conveyors are intended to manage abrasive materials during transportation. The gap between the conveyor screw and the conveyor walls is filled with bulk material. This static layer of material protects the conveyor walls against wear and damage.

Tubular Screw Conveyor

Tubular Screw Conveyors are designed to accommodate bigger screw sizes while also protecting bulk items from environmental variables like dust and weather. They can run at higher speeds and give more capacity each revolution, with conveying angles varying from 1% to 2% according to minute-by-minute readings. These conveyors are also suitable for inclined screw conveyors.

The popularity of tubular screw conveyors stems from their precise operation, which is better than that of "U" shaped conveyors due to the screw's close fit within a fixed volume tube. This design minimizes density shifts, air pockets, and material clumps, especially when the tube vibrates.

Tubular Screw Conveyors are categorized as either non-split or split. Non-split conveyors are one piece, whereas split tubular conveyors are two parts connected by flanges.

jacketed conveyor

A Jacketed Conveyor is a form of screw conveyor designed to retain bulk material at a consistent temperature throughout transit. It does this by heating or cooling the material as it moves down the conveyor. Jacketed conveyors are built up of concentric layers that allow a utility fluid to pass between them, thereby controlling temperature.

conveyor Materials

The material used to construct the conveyor is decided by the application, the kind of screw conveyor, and the level of corrosion or abrasion resistance required.

Mild steel is the most common material used to manufacture screw conveyor conveyors, and it is suitable for any conveying application.

Stainless steel screw conveyors in grades 304 and 316 are used because of their resistance to corrosion, abrasions, and severe impact owing to work hardening.

Abrasion Resistant Steel Grades AR235 or AR400 - Abrasion-resistant steel screw conveyor conveyors are used for abrasive materials because they are two to four times stronger than mild steel.

Electric Motor

Screw Conveyors are powered by an electric motor located at the conveyors discharge end. This configuration allows for the natural flow of bulk material toward the drive end, decreasing stress on the screw flights and minimizing wear and tear on the conveyor components.

Drive Assembly

Screw Conveyors can use a number of driving components. A popular layout consists of a single or double-shaft-mounted speed reducer, a V-belt drive, and a motor mounted on the conveyor housing. The drive assembly may be fitted both vertically and horizontally.

Gear motor drives can use direct low-speed couplings linked to the conveyor shaft or roller chain drives with couplings at the conveyor ends and chains running along the top of the conveyor. Gear drives are popular because of their ability to generate high horsepower and provide variable speed possibilities.

Different Screw Conveyor Configurations

Horizontal Screw Conveyors

Horizontal Screw Conveyors are the most basic form of screw conveyor. They can handle a wide range of bulk material types while efficiently distributing resources to various places via numerous inlets and discharge terminals. These conveyors are commonly constructed with conveyor loading capacities ranging from 15 to 45%.

Conveyor loading refers to the maximum depth at which the conveyor may be filled without generating excessive wear or stress to the screw conveyor components. This capacity is determined by the bulk material being conveyed and is critical for accurate screw conveyor sizing. In general, lightweight, free-flowing, and non-abrasive materials can have higher conveyor loading, whereas thick, heavy, and abrasive substances require lower loading.

Inclined Screw Conveyors

Inclined Screw Conveyors provide an inclined route, eliminating the need for extra conveying equipment when delivering bulk items to or from an elevated area. An option for this kind is to employ two pieces of conveying equipment, one for horizontal and one for vertical transportation. However, this system is more costly and requires more room.

An inclined screw conveyor can be angled anywhere from 0° to 45° above horizontal. As the angle increases, the screw conveyor's efficiency and load capacity decrease, while the power requirement rises due to gravitational force and material fallback. To mitigate these negative outcomes, a conveyor screw with a smaller pitch (one-half or two-thirds of the screw diameter) is used, resulting in a larger conveying surface and less material fallback. Additionally, tubular conveyors assist in reducing material fallback.

Vertical Screw Conveyors

Vertical Screw Conveyors move bulk materials down vertical pathways and very steep inclines with an angle of inclination higher than 45° above the horizontal. They also save space and money when moving big commodities. Controlling the amount of bulk material delivered to vertical screw conveyors is crucial for maintaining a steady speed, reducing wear and power consumption, and increasing conveyor efficiency. Thus, bulk metering systems such as screw feeders are required.

Shaftless Screw Conveyors

Shaftless Screw Conveyors eliminate the requirement for a conveyor shaft screw and internal bearings, resulting in less material buildup and flow restriction. This makes them perfect for transporting sticky, thick, or slow materials. These conveyors make transporting easier and more efficient, and they are frequently used to transport materials from mixers, centrifuges, and filters.

The shaftless spiral of these conveyors enables greater filling rates and lower RPMs, resulting in less wear and lower maintenance requirements. Spirals can be made of a variety of materials, including a specific Swedish steel recognized for its superior mechanical qualities and high tensile strength.

Shaftless spiral conveyors are ideal for carrying municipal dewatered sludge, wastewater screens, grit, industrial sludges, and sticky, viscous, and stringy materials.

Shaftless spiral conveyors have the benefit of being able to move items effectively and straight onto another conveyor, whether horizontally, vertically, or on an incline.

Shaftless Screw Conveyors can be completely enclosed to avoid spills and regulate smells. Furthermore, its direct drive system promotes clean and efficient material movement.

Live Bottom Screw Conveyors

Live Bottom Screw Conveyors are designed to manage and control the volume of bulk materials released from hoppers, bins, and silos. They are commonly installed at the bottom of these containers and are made up of several tapered, variable pitch, or mass flow conveyor screws that control material volume fluctuations at the input. These conveyors can also be used as screw feeders, supplying another screw conveyor.

Flexible Screw Conveyors

Flexible Screw Conveyors consist of a shaftless conveyor screw and a flexible tubular conveyor constructed of UHMW polyethene. Because the conveyor screw and conveyor are comprised of flexible and bendable materials, flexible screw conveyors may move bulk commodities over a broad variety of lengths, angles, and heights.

Flexible Screw Conveyors have a unique design that saves space by allowing the bulk material flow to be readily routed while also allowing for simple positioning of the electric motor and discharge outlet. The conveyor screw can be equipped with either a round or flat spiral design, providing additional flexibility and robustness. For larger feed rates, a flat spiral profile is employed.

Summary

A Screw Conveyor successfully transports enormous volumes of material. The materials might be granular particles, semisolids, liquids, or non-flowing solids.

The screw conveyor consists of the screw conveyor, conveyor, hanger bearings, couplings, internal collar, end lugs, and an electric motor.

Screw Conveyors are divided into several types: standard pitch screw conveyors, variable pitch screw conveyors, half-pitch screw conveyors, long pitch screw conveyors, short pitch screw conveyors, twin flight screw conveyors, tapered flight screw conveyors, and mass flow screw conveyors.

Screw Conveyors with distinctive geometric patterns include cut flight screw conveyors, cut and folded screw conveyors, ribbon screw conveyors, and standard pitch flight screw conveyors with paddles.

Screw Conveyors are divided into two types based on how their flights are designed: helicoid flight screw conveyors and sectional flight screw conveyors.

Screw Conveyors can be either right or left-handed. When the conveyor screw rotates in a specific direction, the direction of material flow is governed by its handedness.

The three fundamental types of conveyors are U-shaped, rectangular, and tubular. U-shaped conveyors are more common. Tubular conveyors are ideal for inclined screw conveyors.

Screw Conveyors are grouped into three types according to their flow path: Horizontal, Inclined, and Vertical. Screw conveyors may also be shaftless or feature a live bottom. The type, maximum particle size, density of the bulk material, volumetric feed rate, mass feed rate, route distance, and environment must all be considered while designing, selecting, and operating a screw conveyor.

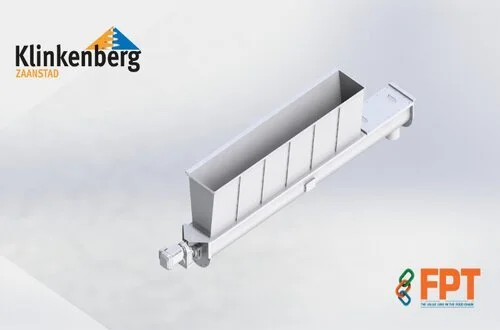

With over 140 years of history, Klinkenberg brings a wealth of experience and cutting-edge technology to its operations, offering a vast range of advanced machinery. Partnering with Klinkenberg, Kiron Food Processing Technologies is now manufacturing in-house screw conveyors right here in India.