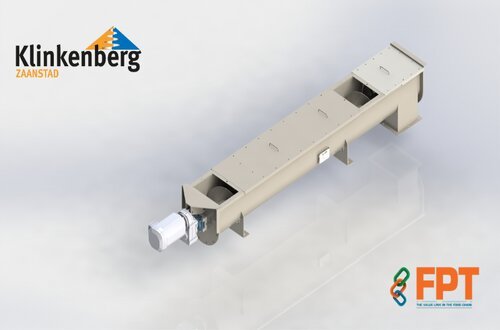

Horizontal Screw Conveyor

Horizontal Screw Conveyors are the most common form of screw conveyor. Horizontal screw conveyors are used to transport bulk items from one stage of a process to another. They come in a variety of sizes, lengths, layouts, and construction materials.

Screw conveyors are used in thousands of industrial applications every day to efficiently carry a wide range of bulk commodities. A screw conveyor's principal function is to transport bulk materials from one activity to another. Screw conveyors are incredibly cost-effective and require minimal maintenance to operate.

The drive unit is best positioned near the discharge end of a screw conveyor, which attracts bulk material to the driving end. This method tensions each screw segment as the bulk material is transported to the discharge of a screw conveyor, reducing wear and stress on the conveyor's components.

Advantages of Horizontal Screw Conveyor

Suitable for transporting dry to semi-fluid bulk materials, from free-flowing to sluggish.

Cost-effective when compared to other conveying methods such as Belt Conveying, Pneumatic Conveying, and Aeromechnical Conveying.

Uses several intake and discharge points to disperse bulk materials efficiently.

Completely enclosed for dusty, corrosive, or dangerous conditions.

Suitable for handling dry to semi-fluid materials (free-flowing to sluggish)

Cost-effective in comparison to other conveying systems such as belt, pneumatic, or aero-mechanical conveyors.

Distributes bulk materials efficiently to numerous places utilizing multiple intake and discharge points.

Completely enclosed for corrosive or hazardous applications.

Primary considerations for screw conveyor

Type and condition of the bulk material to be carried, including the maximum particle size and specific bulk density.

The capacity or feed rate of bulk material to be carried, is represented in pounds per hour, tons per hour, or cubic feet per hour.

The required distance and inclination at which the bulk material will be carried

Design criteria include building materials, intake feed conditions, and operating temperature.

Working Principle of Horizontal Screw Conveyor

The Horizontal Screw Conveyor consists of a rotating shaft and a spiral component that revolves in a closed trough. When material is introduced to the fixed trough, it accumulates on the machine trough owing to gravity and friction.

The material in the lower section of the tank does not rotate with the spiral body but rather travels forward under the push of the spinning spiral blade, similar to the non-rotating nut moving translationally along the rotating screw rod to fulfil the function of transporting materials.

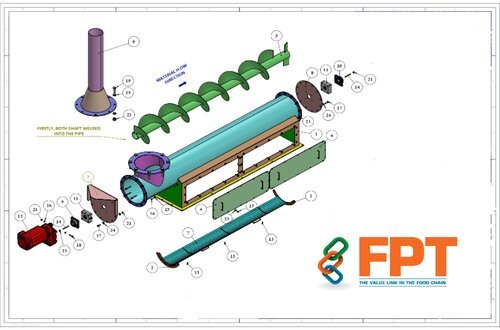

Structure of Horizontal Screw Conveyor

The screw conveyor's construction consists mostly of the driving device, discharge hole, rotating screw axis, bearings, housing, and feeding port, among other components. Screw conveyors often have bearings on the material movement terminal side, which can sustain the material's spiral axial force on the blade. When the conveyor exceeds the fuselage length, a central hanging bearing should be installed.

The Horizontal Screw Conveyor is the most widely used type of screw conveyor due to its simple and user-friendly design. They can transmit materials at 15-45% trough loading, which is calculated as the maximum trough capacity divided by the prescribed trough load for a certain material. A more viscous, slow substance will need a lower trough load, whereas a lighter free-flowing bulk can be fed at a higher load.

A Horizontal Screw Conveyor consists of a driving device, a head assembly, a casing, a shaftless screw body, a trough liner, a material intake, a material exit, a cover (if needed), a base, and so on.

Driving device: A cycloidal pin wheel reducer or a shaft-mounted hard-toothed gear reducer is utilized. When designing, the driving device should be placed as close to the end of the discharge port as feasible, ensuring that the spiral body is tensioned during operation. The head is fitted with a thrust bearing that can withstand the axial force created when transporting materials.

Chassis: The casing is either U-shaped or O-shaped, with a rainproof cover on top made of stainless steel, carbon steel, or glass fibre-reinforced plastic.

Spiral body: The shaft or shaftless design is optional, and the material can be stainless steel or carbon steel.

Tank body lining plate: made of wear-resistant plastic, rubber, or cast stone, among other materials.

Inlets and outlets: There are two types: square and circular. In general, the user chooses the kind of intake and output.

Horizontal Screw Conveyor Manufacturer

Kiron Food Processing Technologies has ten years of expertise in creating Horizontal Screw Conveyors. It contains a full range of models and allows for free selection and drawing design.

It houses a variety of lathes, milling machines, installation and spraying workshops, warehouses, and other processing facilities, as well as cutting and bending machinery.

Machine and polishing machine processing equipment, providing one-stop service from design, drawing, processing, assembly, painting, quality inspection, testing machine, packing, and shipping, with a 12-month quality warranty and lifetime maintenance services.