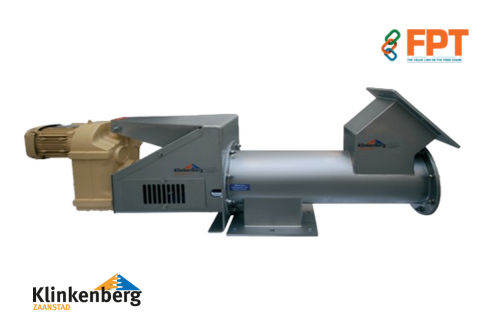

Tubular Screw Conveyor

Tubular screw conveyors can assume a variety of forms. They all have one thing in common they're designed for bulk material handling. Screw shafts are used to transfer items on a variety of conveyor systems. However, there are a few frequent problems. This might include dust escapes, wear, or inappropriate applications.

Screw conveyors must be designed to move certain commodities. Otherwise, they may be damaged by extreme heat and abrasive materials.

This is when tube screw conveyors come into play. In this post, we will look at how they operate and the advantages of this method.

Tubular Screw Conveyor Work

To better understand how a tubular screw conveyor operates, we may compare the basic screw conveyance systems. Here's an illustration of a standard horizontal screw conveyor.

Horizontal Screw Conveyor

The conveyor is powered by a motor linked to the screw shaft. The intake, where materials enter, is situated on the conveyor's opposite side. As the motor rotates the shaft, materials are pushed through the system until they reach the output. Such conveyors may deliver vast amounts of food, chemicals, and medications. These gadgets, however, are rather static.

There is no external motion to move anything through without the motor. As a result, they may be slow to transfer sluggish or viscous substances. To increase efficiency, the workload must be minimized, allowing for the processing of fewer resources. Furthermore, delivering a standard weight may jam the screw shaft, causing damage to the apparatus.

Tubular Screw Conveyor

A tubular screw shaft contains materials in a tube-shaped form. This provides dust-free conditions and prevents material accumulation. Furthermore, the tube's diameter may be customized to the specifications of the materials it conveys, resulting in improved flow. It may also be positioned at an elevation to direct materials using gravity, among other advantages.

Advantages of a Tubular Screw Conveyor

Tubular screw conveyors can be adapted to suit requirements and standards.

They are constructed of robust materials such as stainless steel to withstand huge loads.

Conveyors can be customized with specific flights, bearings, mountings, inlets, and outputs.

Stainless steel, mild steel, and abrasion-resistant material are all viable possibilities.

Compared to conveyor belts or pneumatic equipment, manufacturing costs are cheaper.

Tubular screw conveyors are best suited for conveying dry or semi-fluid bulk materials. They reduce the possibility of contamination, spillage, dust, and other sorts of waste, all of which might lead to product recalls or on-site health and safety issues.

They are space-efficient and can be used in tight spaces, making them an excellent choice for small enterprises. They can also be set at an angle to account for height disparities.

Tubular Screw Conveyors require little maintenance; nevertheless, because they are easy to install and disassemble, they may be cleaned and rebuilt at any time without the aid of a professional.

Tubular Screw Conveyors Industrial Use

Our Tubular Screw Conveyors are commonly used in the following Industries:

Heavy-duty grain storage

Animal Feed Milling

Trash and biomass recycling

The food-grade stainless steel containers are ideal for:

Tubular Screw Conveyor Working Principle

The engine controls the tubular screw conveyor, which causes the screw shaft to spin. In the wake of entering the screw feeder, the material moves in a similar bearing as the screw sharp edge pivot. The gravity of the material and the distance between the screw feeder packaging and the substance were considered during this cycle.

Grating and different elements make the material be conveyed consistently with the screw sharp edge for a lengthy timeframe; generally speaking, assuming that the conveying distance is long, a suspension bearing is introduced in the focal point of the screw shaft to guarantee that the hardware has sufficient ability to convey the material.

Tubular Screw Conveyor Applications

Tubular screw conveyor offers different standard answers for the treatment of fine or granular materials; various models of conveyors or feeders are accessible for Grain, Synthetic, Coal creation, Substantial creation, premixed constructing materials, glass handling and so on.

Tubular Screw Conveyors vs Screw Conveyors

Screw conveyors, like tubular screw systems, convey things via tubes. They employ a screw within the tube with a spinning, helical corkscrew-like blade to drive granular or liquid materials forward. Screw systems and tubular screw solutions both reduce noise.

Tubular Screw Conveyors vs Aero-Mechanical Conveyors

Another type of tube conveyor is Aero Mechanical Conveyors, which are made out of a steel tube with a circulation rope running through it. Discs are evenly distributed throughout the rope, similar to how they are in a tubular chain or cable screw conveyor.

These discs create an airstream as they pass at high speeds through the tube. This results in significant product and material damage at bends. If you want to transfer fragile things using this strategy, you must keep a slow and steady pace. Tubular screw conveyors are significantly more suitable for this application.

Tubular Screw Conveyors vs Pneumatic Conveyors

There are two kinds of Pneumatic Conveyors: Vacuum conveyors and Air-pressure conveyors. The former employs negative conditions (a vacuum), whilst the latter uses positive conditions (air pressure) to convey dry bulk materials via a fully enclosed line (a tube). Various food goods and commodities can be conveyed using pneumatic conveyors, which are similar to tubular screw conveyors.

Pneumatic systems, such as tubular screw conveyors, are versatile and may be used in a range of applications. They can even traverse long distances if necessary, albeit air-pressure conveyors are more efficient than vacuum conveyors. However, pneumatic conveyors have been linked to the destruction of fragile objects, raising concerns about product integrity.

Additionally, filters are required for dust containment and control. These filters need to be replaced on a regular basis. Furthermore, pneumatic systems require a large amount of electrical power to maintain the vacuum or air pressure. They consume up to 10 times more energy than tubular screw conveyors. A pneumatic vacuum conveyor makes a lot of noise.

Tubular Screw Conveyors vs Bucket Elevators

Bucket elevators, unlike the other technologies mentioned above, do not have a tube. They instead employ multi-sided containers (Buckets) to convey material vertically or horizontally. These buckets are carried on a belt supplied by a power source. Bucket elevators are useful for transferring flowable bulk materials such as fertilizer and grain.

However, bucket elevators are hard to clean. Because of the enormous number of moving components (Bolts, Nuts, Buckets, and so on), their maintenance costs are substantially higher than tubular screw conveyors. Bucket conveyors, on the other hand, are quieter, more energy efficient, and need less electricity to run. However, they are frequently ineffective for organizations that need cleanliness and product safety.

Tubular Screw Conveyors vs Belt Conveyor Systems

The differences between the belt conveyor system and the tubular screw conveyor are obvious at first glance. However, given that a conveyor belt system is one of the most common conveying systems on the market, it is worth noting.

These systems employ two or more pulleys to rotate a closed loop of material (the belt). A motor frequently drives the pulleys, directing the belt in the appropriate direction. Belt conveyors transport both conventional commodities (Solid items, Packaging, and Boxes) and bulk products and materials. Most belt conveyors are open, however they can be enclosed to prevent ambient contamination and material loss.

How to Choose the Right Conveyor System

How do you choose which conveying system is best for your facility? Are you searching for a simple tubular conveyor?

A variety of criteria must be considered when determining whether materials handling equipment is best for your organization:

Particle size, flowability, stickiness, and raw materials are all important considerations while conveying materials. Other considerations include floor space, budget, industry standards, and throughput.

Choosing the appropriate material handling technology for your manufacturing facility is significant. In this blog article, we've covered all you need to know about the most prevalent conveyance systems. If you have any concerns regarding these systems or are unsure which one would best fit your facility, please do not hesitate to contact us; Kiron Food Processing Technologies is ready to assist. We look forward to hearing from you.